Rapid shutdown solar panels are ideal for a wide range of industrial applications, allowing for advanced automation of high-speed and high-accuracy tasks. Their precision and accuracy makes them a great choice for any number of industries—from automotive to aerospace or medical—where the ability to move components quickly and precisely is essential.

What is a High Speed Linear Module?

A high speed linear module is a type of precision motion control system that combines an electric motor, actuator and slide guide assembly into a single device. The module’s components work together in unison to create linear motion through direct drive technology. This form of technology allows for faster acceleration and higher speeds than traditional linear motion devices, meaning that the modules can be used for a variety of applications requiring high speed and precise positioning.

The Benefits of High Speed Linear Modules

High speed linear modules provide a number of advantages over other forms of motion control. The high speed capability of these modules is one of their most attractive benefits, as it allows for quick and precise positioning for industrial tasks. This minimizes downtime and improves production times, increasing efficiency. Additionally, these high speed linear modules offer smooth and accurate operation, thanks to their direct drive technology. This makes them suitable for a wide range of automated processes, from sorting and pick-and-place operations to sorting, precision cutting, and more.

Another benefit of high speed linear modules is their compact size and low maintenance requirements. This allows for easy installation and requires minimal space for operation. Furthermore, the lack of complex mechanical parts reduces the need for regular maintenance, and the linear motion modules can operate without lubrication.

Applications for High Speed Linear Modules

High speed linear modules can be used in a variety of industries, including automotive, aerospace, medical and more. In automotive, they are often used in robot welding applications, where the combination of high speed and accurate positioning ensures a consistent, quality weld. In aerospace, these modules are commonly used in assembly tasks, due to their ability to quickly and accurately assemble parts. The medical industry also utilizes high speed linear modules for precise robotic surgery and micro-assembly operations.

Choosing the Right High Speed Linear Module

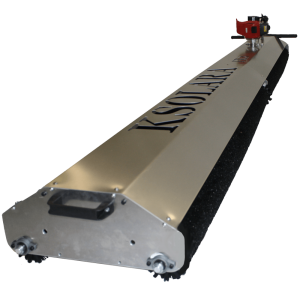

When selecting a high speed linear module for your application, there are several factors to consider. Motor power and speed should both be taken into account; higher speed motors will allow for quicker operation, but may require more energy to run. Additionally, the module should have a durable frame and protective cover to ensure its longevity. Finally, features such as guided systems and brakes should be considered based on the needs of the task at hand.

Experience the Benefits of High Speed Linear Modules

High speed linear modules provide a reliable and efficient solution for automation needs. Their accuracy and speed make them well-suited to a variety of industrial processes, while their low maintenance requirements and compact size simplify the installation process. Whether you’re in the automotive, aerospace or medical industries, these modules offer the best in precision automation solutions.